Published on Jun 15, 2012

I am trying a new intro and will be

experimenting with some editing later on to try and make the my videos

more interesting...

I just watched John over at http://www.growingyourgreens.com/ and picked up a few tips on how to make a more enjoyable video for you to watch.

Cantaloupe (also canteloupe, cantaloup, muskmelon (India), mushmelon, muskmelon, rockmelon, sweet melon, Persian melon, spanspek (South Africa), or Garma گرما) refers to a variety of Cucumis melo, a species in the family Cucurbitaceae.

Cantaloupes range in size from 500 g to 5 kg (1 to 10 lb).

Originally, cantaloupe referred only to the non-netted, orange-fleshed melons of Europe. However, in more recent usage, it has come to mean any orange-fleshed melon (C. melo). Cantaloupe is the most popular variety of melon in the United States.[2]

Tradition has it that this is where it was first cultivated in Europe, on its introduction from Ancient Armenia.[3] Its first known usage in English dates from 1739 in The Gardeners Dictionary Vol. II by Scottish botanist Philip Miller (1691–1771).[3]

Cantaloupes range in size from 500 g to 5 kg (1 to 10 lb).

Originally, cantaloupe referred only to the non-netted, orange-fleshed melons of Europe. However, in more recent usage, it has come to mean any orange-fleshed melon (C. melo). Cantaloupe is the most popular variety of melon in the United States.[2]

| Cantaloupe | |

|---|---|

|

|

| Scientific classification | |

| Kingdom: | Plantae |

| (unranked): | Angiosperms |

| (unranked): | Eudicots |

| (unranked): | Rosids |

| Order: | Cucurbitales |

| Family: | Cucurbitaceae |

| Genus: | Cucumis |

| Species: | C. melo |

| Subspecies: | C. melo subsp. melo |

| Variety: | C. melo var. cantalupensis |

| Trinomial name | |

| Cucumis melo var. cantalupensis[1] Naudin |

|

| Synonyms | |

| Cucumis melo var. reticulatus Naudin[1] | |

Etymology

The name is derived, via French, from the Italian Cantalupo which was formerly a papal county seat near Rome.Tradition has it that this is where it was first cultivated in Europe, on its introduction from Ancient Armenia.[3] Its first known usage in English dates from 1739 in The Gardeners Dictionary Vol. II by Scottish botanist Philip Miller (1691–1771).[3]

Origin

The cantaloupe originated in Iran, India and Africa;[4] it was first cultivated in Iran some 5000 years ago and in Greece and Egypt some 4000 years ago.[5]Cantaloupes by region

The North American cantaloupe, common in the United States, Mexico, and in some parts of Canada, is actually a muskmelon, a different variety of Cucumis melo, and has a net-like (or reticulated) skin covering.

It is a round melon

with firm, orange, moderately sweet flesh and a thin, reticulated,

light-brown rind.[6]

Varieties with redder and yellower flesh exist, but are not common in the U.S. market.[citation needed]

Because they are descended from tropical plants

and tend to require warm temperatures throughout a relatively long

growing period, cantaloupes grown in temperate climates are frequently

started indoors for 14 days or longer before being transplanted

outdoors.

Cantaloupes are often picked, and shipped, before fully ripening. Postharvest practices include treatment with a sodium hypochlorite or bleach wash to prevent mold and Salmonella growth. This treatment, because it can mask the melon's musky aroma, can make it difficult for the purchaser to judge the relative quality of different cantaloupes.

Cantaloupe is normally eaten as a fresh fruit, as a salad, or as a dessert with ice cream or custard. Melon pieces wrapped in prosciutto are a familiar antipasto.

Because the surface of a cantaloupe can contain harmful bacteria—in particular, Salmonella [7]—it is always a good idea to wash and scrub a melon thoroughly before cutting and consumption. The fruit should be refrigerated for less than three days after cutting to prevent risk of Salmonella or other bacterial pathogens.[8]

A mouldy cantaloupe in a Peoria, Illinois market in 1941 was found to contain the best and highest quality penicillin, after a worldwide search.[9]

Production and uses

Cantaloupes are often picked, and shipped, before fully ripening. Postharvest practices include treatment with a sodium hypochlorite or bleach wash to prevent mold and Salmonella growth. This treatment, because it can mask the melon's musky aroma, can make it difficult for the purchaser to judge the relative quality of different cantaloupes.

Cantaloupe is normally eaten as a fresh fruit, as a salad, or as a dessert with ice cream or custard. Melon pieces wrapped in prosciutto are a familiar antipasto.

Because the surface of a cantaloupe can contain harmful bacteria—in particular, Salmonella [7]—it is always a good idea to wash and scrub a melon thoroughly before cutting and consumption. The fruit should be refrigerated for less than three days after cutting to prevent risk of Salmonella or other bacterial pathogens.[8]

A mouldy cantaloupe in a Peoria, Illinois market in 1941 was found to contain the best and highest quality penicillin, after a worldwide search.[9]

| Nutritional value per 100 g (3.5 oz) | |

|---|---|

| Energy | 141 kJ (34 kcal) |

| Carbohydrates | 8.16 g |

| - Sugars | 7.86 g |

| - Dietary fiber | 0.9 g |

| Fat | 0.19 g |

| Protein | 0.84 g |

| Vitamin A equiv. | 169 μg (21%) |

| - beta-carotene | 2020 μg (19%) |

| - lutein and zeaxanthin | 26 μg |

| Thiamine (vit. B1) | 0.041 mg (4%) |

| Riboflavin (vit. B2) | 0.019 mg (2%) |

| Niacin (vit. B3) | 0.734 mg (5%) |

| Pantothenic acid (B5) | 0.105 mg (2%) |

| Vitamin B6 | 0.072 mg (6%) |

| Folate (vit. B9) | 21 μg (5%) |

| Choline | 7.6 mg (2%) |

| Vitamin C | 36.7 mg (44%) |

| Vitamin K | 2.5 μg (2%) |

| Calcium | 9 mg (1%) |

| Iron | 0.21 mg (2%) |

| Magnesium | 12 mg (3%) |

| Manganese | 0.41 mg (20%) |

| Phosphorus | 15 mg (2%) |

| Potassium | 267 mg (6%) |

| Sodium | 16 mg (1%) |

| Zinc | 0.18 mg (2%) |

| Link to USDA Database entry Percentages are roughly approximated using US recommendations for adults. Source: USDA Nutrient Database | |

Source:Wikipedia.org

Somebody Come and Play Today! Earn as You Learn, Grow as You Go!

The Man Inside the Man

from

Sinbad the Sailor Man

A

JMK's Production

Share this page

TTFN

CYA Later Taters!

Thanks for stopping by.

Donnie/Sinbad the Sailor Man

P.S. Sweet Sixteen My Breakout Year's Hottest and Fastest Growing Biz Op? Do You Want In? If You Do! Click Here and Sign Up!

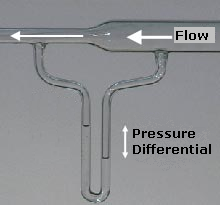

is the

is the  is the (slower) fluid velocity where the pipe is wider,

is the (slower) fluid velocity where the pipe is wider,  is the (faster) fluid velocity where the pipe is narrower (as seen in

the figure). This assumes the flowing fluid (or other substance) is not

significantly compressible - even though pressure varies, the density is

assumed to remain approximately constant.

is the (faster) fluid velocity where the pipe is narrower (as seen in

the figure). This assumes the flowing fluid (or other substance) is not

significantly compressible - even though pressure varies, the density is

assumed to remain approximately constant.